Grounding of commercial and industrial power systems

Grounding is an important aspect of every electrical distribution system. A properly designed and well maintained grounding system significantly reduces the chance of personnel electrocution, electrical fires, equipment damage and associated downtime. This page addresses the basics of grounding and outlines the need for regularly scheduled maintenance and testing activities for grounding systems. The National Electric Code (NEC), Article 250, contains specific requirements on the grounding of electrical power systems and equipment. In all cases, the requirements of the NEC should be followed. Grounding is covered in greater detail in HSB's Recommended Practices for Grounding of Commercial and Industrial Power Systems.

Basics of grounding

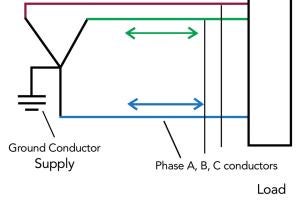

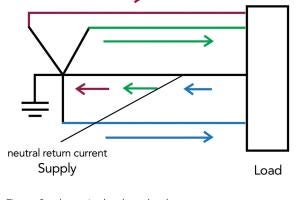

For a piece of electrical equipment to operate, a complete path for current flow must exist between the source of the power and the piece of electrical equipment. For a three-phase system (Figure 1), current flows between the source and the piece of equipment on the three-phase conductors, phase A, phase B and phase C. On a single-phase system (Figure 2), current flows from the source to the piece of equipment on a single conductor (sometimes called the hot leg) and returns to the source on the neutral or common conductor. A neutral or common conductor can also be used to establish a voltage reference. This is required for certain circuits to operate properly. A neutral or common conductor can be grounded, but a neutral or common conductor is not an equipment safety ground.

The grounding of electrical equipment is the deliberate connection of exposed metal surfaces of electrical equipment to the earth (ground) for personnel safety. Electrical equipment such as transformers, motors, switchgear, cable and bus contain energized and non-energized components. When an energized component comes in contact with a metal case or structure of a piece of equipment, it is commonly known

as a ground fault. If a ground fault occurs, the case or structure will be at system voltage. This is a very dangerous situation. When a metallic object or person touches the equipment, current will flow through the object or person to ground. This can severely injure or kill the person and will cause extensive equipment damage. A properly designed, installed and maintained grounding system can prevent this from occurring.

Types of grounds

A grounding system is composed of a system ground and equipment grounds.

A system ground is ground rod(s) bonded together and connected to the power supply of the system. Ground rods can be metallic spikes driven into the ground, rebar, structural building steel and metal underground pipe or any combination of these.

Equipment grounds must provide a path from the equipment to the system ground. Equipment grounds can be conductors, metallic conduit or cable raceways.

In addition to a personnel safety equipment ground, electronic equipment such as computers and control equipment may require additional equipment grounds for proper operation. These grounds must be connected at a single point to the ground. Electronic equipment cannot have separate system grounds.

Ground faults

There are two types of ground faults, solid ground faults and intermittent ground faults. Solid ground faults occur when an energized component comes in contact and stays in contact with ground. This type of ground fault results in a very large current draw and will typically cause a fuse to open or a breaker to trip on overcurrent. An intermittent ground fault will intermittently connect an energized component to ground.

This type of ground causes significantly less fault current and will not consistently cause overcurrent protective devices to operate. This fault will result in arcing and heating and can result in fire and equipment damage. Ground fault protection is used to protect against ground faults. Ground fault protection senses a ground fault condition and automatically opens the supply breaker.

Recommended inspection and maintenance activities

Over time grounding systems that are not maintained become less effective. This can be due to changes in the electrical system, changes in the water table, loose connections, replacement of underground metal pipes with non-metallic pipes, corrosion or improper work on the electrical system. This degradation can cause injuries, fires and equipment damage on systems with previously adequate grounding systems. After any major change to an electrical distribution system, every three years (maximum), or if ground-related issues are suspected, a qualified electrical contractor or professional engineer should verify the grounding system is in accordance with the National Electric Code Article 250.

© 2010 The Hartford Steam Boiler Inspection and Insurance Company. All Rights Reserved. Used with permission of The Hartford Steam Boiler Inspection and Insurance Company.

This material is provided for informational purposes only and does not provide any coverage or guarantee loss prevention. The examples in this material are provided as hypothetical and for illustration purposes only. The Hanover Insurance Company and its affiliates and subsidiaries (“The Hanover”) specifically disclaim any warranty or representation that acceptance of any recommendations contained herein will make any premises, or operation safe or in compliance with any law or regulation. By providing this information to you, The Hanover does not assume (and specifically disclaims) any duty, undertaking or responsibility to you. The decision to accept or implement any recommendation(s) or advice contained in this material must be made by you.

LC MAR 2019 2015-410

171-9273 (03/16)

Related resources

Grounding of commercial and industrial power systems

Grounding is an important aspect of every electrical distribution system. A properly designed and well maintained grounding system significantly reduces the chance of personnel electrocution, electrical fires, equipment damage and associated downtime. This page addresses the basics of grounding and outlines the need for regularly scheduled maintenance and testing activities for grounding systems. The National Electric Code (NEC), Article 250, contains specific requirements on the grounding of electrical power systems and equipment. In all cases, the requirements of the NEC should be followed. Grounding is covered in greater detail in HSB's Recommended Practices for Grounding of Commercial and Industrial Power Systems.

Basics of grounding

For a piece of electrical equipment to operate, a complete path for current flow must exist between the source of the power and the piece of electrical equipment. For a three-phase system (Figure 1), current flows between the source and the piece of equipment on the three-phase conductors, phase A, phase B and phase C. On a single-phase system (Figure 2), current flows from the source to the piece of equipment on a single conductor (sometimes called the hot leg) and returns to the source on the neutral or common conductor. A neutral or common conductor can also be used to establish a voltage reference. This is required for certain circuits to operate properly. A neutral or common conductor can be grounded, but a neutral or common conductor is not an equipment safety ground.

The grounding of electrical equipment is the deliberate connection of exposed metal surfaces of electrical equipment to the earth (ground) for personnel safety. Electrical equipment such as transformers, motors, switchgear, cable and bus contain energized and non-energized components. When an energized component comes in contact with a metal case or structure of a piece of equipment, it is commonly known

as a ground fault. If a ground fault occurs, the case or structure will be at system voltage. This is a very dangerous situation. When a metallic object or person touches the equipment, current will flow through the object or person to ground. This can severely injure or kill the person and will cause extensive equipment damage. A properly designed, installed and maintained grounding system can prevent this from occurring.

Types of grounds

A grounding system is composed of a system ground and equipment grounds.

A system ground is ground rod(s) bonded together and connected to the power supply of the system. Ground rods can be metallic spikes driven into the ground, rebar, structural building steel and metal underground pipe or any combination of these.

Equipment grounds must provide a path from the equipment to the system ground. Equipment grounds can be conductors, metallic conduit or cable raceways.

In addition to a personnel safety equipment ground, electronic equipment such as computers and control equipment may require additional equipment grounds for proper operation. These grounds must be connected at a single point to the ground. Electronic equipment cannot have separate system grounds.

Ground faults

There are two types of ground faults, solid ground faults and intermittent ground faults. Solid ground faults occur when an energized component comes in contact and stays in contact with ground. This type of ground fault results in a very large current draw and will typically cause a fuse to open or a breaker to trip on overcurrent. An intermittent ground fault will intermittently connect an energized component to ground.

This type of ground causes significantly less fault current and will not consistently cause overcurrent protective devices to operate. This fault will result in arcing and heating and can result in fire and equipment damage. Ground fault protection is used to protect against ground faults. Ground fault protection senses a ground fault condition and automatically opens the supply breaker.

Recommended inspection and maintenance activities

Over time grounding systems that are not maintained become less effective. This can be due to changes in the electrical system, changes in the water table, loose connections, replacement of underground metal pipes with non-metallic pipes, corrosion or improper work on the electrical system. This degradation can cause injuries, fires and equipment damage on systems with previously adequate grounding systems. After any major change to an electrical distribution system, every three years (maximum), or if ground-related issues are suspected, a qualified electrical contractor or professional engineer should verify the grounding system is in accordance with the National Electric Code Article 250.

© 2010 The Hartford Steam Boiler Inspection and Insurance Company. All Rights Reserved. Used with permission of The Hartford Steam Boiler Inspection and Insurance Company.

This material is provided for informational purposes only and does not provide any coverage or guarantee loss prevention. The examples in this material are provided as hypothetical and for illustration purposes only. The Hanover Insurance Company and its affiliates and subsidiaries (“The Hanover”) specifically disclaim any warranty or representation that acceptance of any recommendations contained herein will make any premises, or operation safe or in compliance with any law or regulation. By providing this information to you, The Hanover does not assume (and specifically disclaims) any duty, undertaking or responsibility to you. The decision to accept or implement any recommendation(s) or advice contained in this material must be made by you.

LC MAR 2019 2015-410

171-9273 (03/16)

Related resources

Grounding of commercial and industrial power systems

Grounding is an important aspect of every electrical distribution system. A properly designed and well maintained grounding system significantly reduces the chance of personnel electrocution, electrical fires, equipment damage and associated downtime. This page addresses the basics of grounding and outlines the need for regularly scheduled maintenance and testing activities for grounding systems. The National Electric Code (NEC), Article 250, contains specific requirements on the grounding of electrical power systems and equipment. In all cases, the requirements of the NEC should be followed. Grounding is covered in greater detail in HSB's Recommended Practices for Grounding of Commercial and Industrial Power Systems.

Basics of grounding

For a piece of electrical equipment to operate, a complete path for current flow must exist between the source of the power and the piece of electrical equipment. For a three-phase system (Figure 1), current flows between the source and the piece of equipment on the three-phase conductors, phase A, phase B and phase C. On a single-phase system (Figure 2), current flows from the source to the piece of equipment on a single conductor (sometimes called the hot leg) and returns to the source on the neutral or common conductor. A neutral or common conductor can also be used to establish a voltage reference. This is required for certain circuits to operate properly. A neutral or common conductor can be grounded, but a neutral or common conductor is not an equipment safety ground.

The grounding of electrical equipment is the deliberate connection of exposed metal surfaces of electrical equipment to the earth (ground) for personnel safety. Electrical equipment such as transformers, motors, switchgear, cable and bus contain energized and non-energized components. When an energized component comes in contact with a metal case or structure of a piece of equipment, it is commonly known

as a ground fault. If a ground fault occurs, the case or structure will be at system voltage. This is a very dangerous situation. When a metallic object or person touches the equipment, current will flow through the object or person to ground. This can severely injure or kill the person and will cause extensive equipment damage. A properly designed, installed and maintained grounding system can prevent this from occurring.

Types of grounds

A grounding system is composed of a system ground and equipment grounds.

A system ground is ground rod(s) bonded together and connected to the power supply of the system. Ground rods can be metallic spikes driven into the ground, rebar, structural building steel and metal underground pipe or any combination of these.

Equipment grounds must provide a path from the equipment to the system ground. Equipment grounds can be conductors, metallic conduit or cable raceways.

In addition to a personnel safety equipment ground, electronic equipment such as computers and control equipment may require additional equipment grounds for proper operation. These grounds must be connected at a single point to the ground. Electronic equipment cannot have separate system grounds.

Ground faults

There are two types of ground faults, solid ground faults and intermittent ground faults. Solid ground faults occur when an energized component comes in contact and stays in contact with ground. This type of ground fault results in a very large current draw and will typically cause a fuse to open or a breaker to trip on overcurrent. An intermittent ground fault will intermittently connect an energized component to ground.

This type of ground causes significantly less fault current and will not consistently cause overcurrent protective devices to operate. This fault will result in arcing and heating and can result in fire and equipment damage. Ground fault protection is used to protect against ground faults. Ground fault protection senses a ground fault condition and automatically opens the supply breaker.

Recommended inspection and maintenance activities

Over time grounding systems that are not maintained become less effective. This can be due to changes in the electrical system, changes in the water table, loose connections, replacement of underground metal pipes with non-metallic pipes, corrosion or improper work on the electrical system. This degradation can cause injuries, fires and equipment damage on systems with previously adequate grounding systems. After any major change to an electrical distribution system, every three years (maximum), or if ground-related issues are suspected, a qualified electrical contractor or professional engineer should verify the grounding system is in accordance with the National Electric Code Article 250.

© 2010 The Hartford Steam Boiler Inspection and Insurance Company. All Rights Reserved. Used with permission of The Hartford Steam Boiler Inspection and Insurance Company.

This material is provided for informational purposes only and does not provide any coverage or guarantee loss prevention. The examples in this material are provided as hypothetical and for illustration purposes only. The Hanover Insurance Company and its affiliates and subsidiaries (“The Hanover”) specifically disclaim any warranty or representation that acceptance of any recommendations contained herein will make any premises, or operation safe or in compliance with any law or regulation. By providing this information to you, The Hanover does not assume (and specifically disclaims) any duty, undertaking or responsibility to you. The decision to accept or implement any recommendation(s) or advice contained in this material must be made by you.

LC MAR 2019 2015-410

171-9273 (03/16)

Related resources

Grounding of commercial and industrial power systems

Grounding is an important aspect of every electrical distribution system. A properly designed and well maintained grounding system significantly reduces the chance of personnel electrocution, electrical fires, equipment damage and associated downtime. This page addresses the basics of grounding and outlines the need for regularly scheduled maintenance and testing activities for grounding systems. The National Electric Code (NEC), Article 250, contains specific requirements on the grounding of electrical power systems and equipment. In all cases, the requirements of the NEC should be followed. Grounding is covered in greater detail in HSB's Recommended Practices for Grounding of Commercial and Industrial Power Systems.

Basics of grounding

For a piece of electrical equipment to operate, a complete path for current flow must exist between the source of the power and the piece of electrical equipment. For a three-phase system (Figure 1), current flows between the source and the piece of equipment on the three-phase conductors, phase A, phase B and phase C. On a single-phase system (Figure 2), current flows from the source to the piece of equipment on a single conductor (sometimes called the hot leg) and returns to the source on the neutral or common conductor. A neutral or common conductor can also be used to establish a voltage reference. This is required for certain circuits to operate properly. A neutral or common conductor can be grounded, but a neutral or common conductor is not an equipment safety ground.

The grounding of electrical equipment is the deliberate connection of exposed metal surfaces of electrical equipment to the earth (ground) for personnel safety. Electrical equipment such as transformers, motors, switchgear, cable and bus contain energized and non-energized components. When an energized component comes in contact with a metal case or structure of a piece of equipment, it is commonly known

as a ground fault. If a ground fault occurs, the case or structure will be at system voltage. This is a very dangerous situation. When a metallic object or person touches the equipment, current will flow through the object or person to ground. This can severely injure or kill the person and will cause extensive equipment damage. A properly designed, installed and maintained grounding system can prevent this from occurring.

Types of grounds

A grounding system is composed of a system ground and equipment grounds.

A system ground is ground rod(s) bonded together and connected to the power supply of the system. Ground rods can be metallic spikes driven into the ground, rebar, structural building steel and metal underground pipe or any combination of these.

Equipment grounds must provide a path from the equipment to the system ground. Equipment grounds can be conductors, metallic conduit or cable raceways.

In addition to a personnel safety equipment ground, electronic equipment such as computers and control equipment may require additional equipment grounds for proper operation. These grounds must be connected at a single point to the ground. Electronic equipment cannot have separate system grounds.

Ground faults

There are two types of ground faults, solid ground faults and intermittent ground faults. Solid ground faults occur when an energized component comes in contact and stays in contact with ground. This type of ground fault results in a very large current draw and will typically cause a fuse to open or a breaker to trip on overcurrent. An intermittent ground fault will intermittently connect an energized component to ground.

This type of ground causes significantly less fault current and will not consistently cause overcurrent protective devices to operate. This fault will result in arcing and heating and can result in fire and equipment damage. Ground fault protection is used to protect against ground faults. Ground fault protection senses a ground fault condition and automatically opens the supply breaker.

Recommended inspection and maintenance activities

Over time grounding systems that are not maintained become less effective. This can be due to changes in the electrical system, changes in the water table, loose connections, replacement of underground metal pipes with non-metallic pipes, corrosion or improper work on the electrical system. This degradation can cause injuries, fires and equipment damage on systems with previously adequate grounding systems. After any major change to an electrical distribution system, every three years (maximum), or if ground-related issues are suspected, a qualified electrical contractor or professional engineer should verify the grounding system is in accordance with the National Electric Code Article 250.

© 2010 The Hartford Steam Boiler Inspection and Insurance Company. All Rights Reserved. Used with permission of The Hartford Steam Boiler Inspection and Insurance Company.

This material is provided for informational purposes only and does not provide any coverage or guarantee loss prevention. The examples in this material are provided as hypothetical and for illustration purposes only. The Hanover Insurance Company and its affiliates and subsidiaries (“The Hanover”) specifically disclaim any warranty or representation that acceptance of any recommendations contained herein will make any premises, or operation safe or in compliance with any law or regulation. By providing this information to you, The Hanover does not assume (and specifically disclaims) any duty, undertaking or responsibility to you. The decision to accept or implement any recommendation(s) or advice contained in this material must be made by you.

LC MAR 2019 2015-410

171-9273 (03/16)